Can Robots Enhance Manufacturing Precision?

Welcome, dear readers! Today, we’ll delve deep into the world of robots and their role in the manufacturing process. More specifically, we’ll explore whether these mechanical marvels can enhance precision in manufacturing. For those of you who are new to this fascinating topic, don’t worry! We’ll take you on an easy-to-understand journey that will illuminate the intersection between robotics and manufacturing precision.

The Role of Robots in Manufacturing

Before we can fully understand the impact of robots on manufacturing precision, we must first understand their role in the manufacturing industry.

Sujet a lire : What is the information on chatbot-related events and conferences ?

Robots have been a part of the manufacturing process for several decades, but their importance has grown exponentially over the years. They have transitioned from simple, single-task machines to sophisticated entities capable of multi-faceted functions and processes.

Robots are often assigned tasks that are deemed too dangerous, difficult, or repetitive for human workers. This could involve handling hazardous materials, assembling intricate parts, or performing repetitive tasks with consistent precision. As they are programmed to follow specific instructions, robots can carry out these tasks with a degree of accuracy and consistency that humans often can’t match.

A lire aussi : The role of big data in understanding consumer behavior

The Impact of Robotics on Precision Manufacturing

Robots are known for their superior precision and consistency compared to their human counterparts. But how does this translate into the manufacturing process?

Firstly, robots are programmed to follow the exact actions defined for them, down to millimeter precision. This allows them to deliver incredible accuracy when it comes to assembly or production tasks. This level of precision reduces the risk of errors and defects, which translates into higher quality products.

Secondly, robots are capable of performing tasks at a consistent speed and quality over long durations. Unlike humans, robots don’t tire or get bored, which means they can maintain the same level of precision over endless repetitions of the same task. This consistency is critical in ensuring that every product coming off the assembly line meets the same high standards.

The Future of Robotics in Precision Manufacturing

The potential of robots in enhancing precision in manufacturing is immense, and we are only scratching the surface. With advancements in Artificial Intelligence (AI) and Machine Learning, robots are becoming smarter and more autonomous. They can now learn from their mistakes and improve their performance over time.

AI-powered robots can analyze vast amounts of data to identify patterns and make predictions, reducing the need for human intervention in the manufacturing process and increasing the level of precision. This intelligence also allows robots to adapt to changes in the manufacturing process, further enhancing their precision and efficiency.

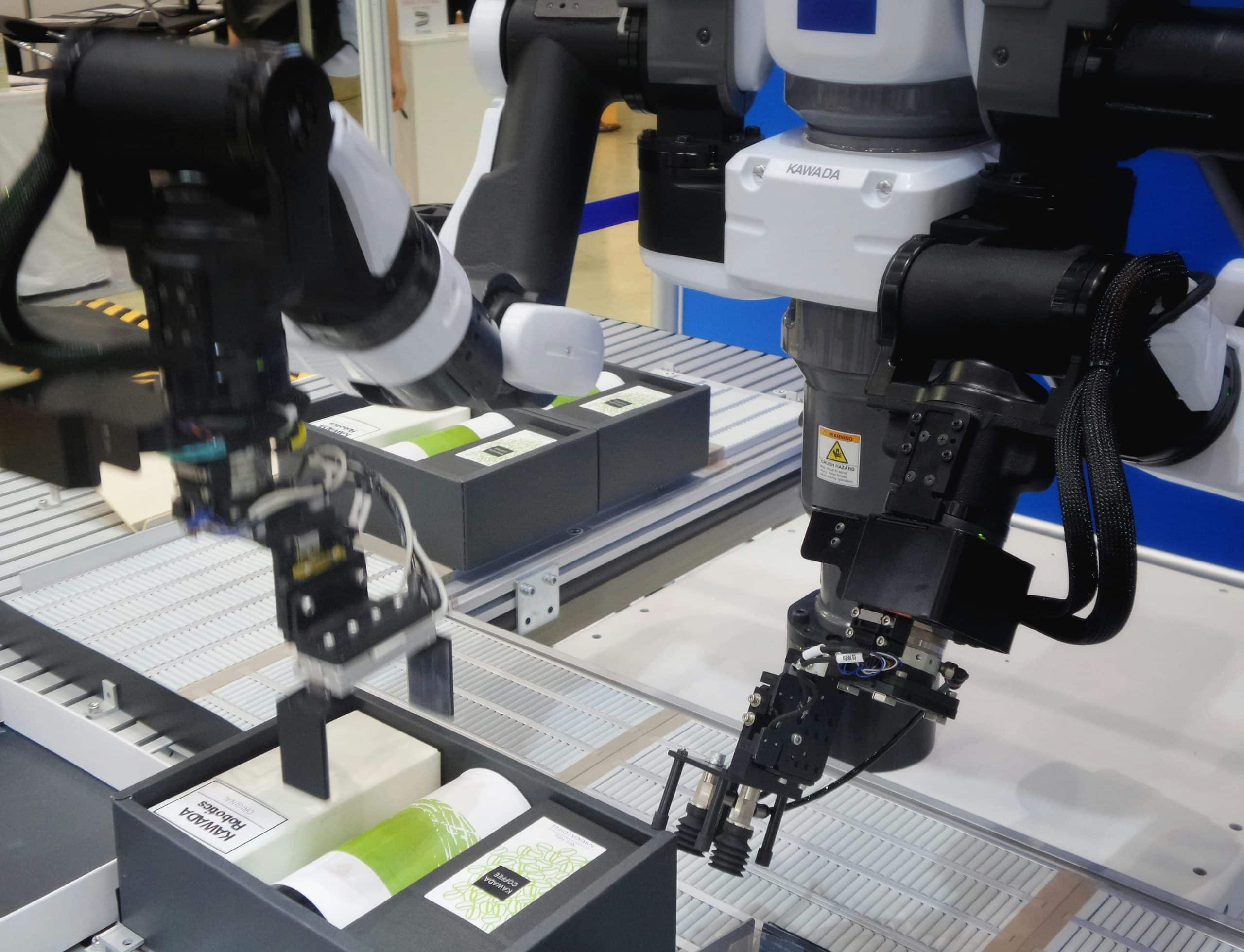

Moreover, the emergence of collaborative robots, or cobots, promises a future where humans and robots can work side-by-side in the manufacturing process. These cobots are designed to interact with human workers in a shared workspace, combining the strengths of both parties for optimum precision and efficiency.

Robotic Precision: A Boon for Manufacturing Industries

The ability of robots to enhance precision in manufacturing is not just a theoretical concept. It’s already making a significant impact in various manufacturing industries.

Take the automotive industry, for example. Robots are used to assemble various car components with high precision, which is crucial for the safety and performance of the vehicles. Similarly, in the electronics industry, robots are used to assemble tiny, intricate components with a degree of precision that would be almost impossible for humans to achieve.

In the medical device manufacturing industry, the use of robots is transforming the production of life-saving devices. Robots are used to manufacture medical devices with high precision, ensuring that they function flawlessly and meet stringent regulatory standards.

The application of robotic precision in these and other industries not only ensures the production of high-quality products but also leads to cost savings and improved efficiency. Through more accurate and consistent production, there is less wastage, fewer recalls, and increased productivity.

In a nutshell, the advent of robotics has ushered in a new era of precision in manufacturing. Robots are no longer mere tools; they have become indispensable allies in the quest for precision and perfection in the manufacturing process. As we move forward, it’s clear that the role of robotics in enhancing manufacturing precision will only continue to grow.

The Challenges and Solutions in Precision Robotics

While the benefits of robotics in manufacturing precision are clear, it would be remiss not to acknowledge the challenges that come with it. With the increase in autonomy and complexity of robots, the risk of malfunctions or errors can also increase. This could potentially lead to costly production delays or defective products.

The precision of robots relies heavily on the accuracy of their programming and calibration. Any error in these areas could lead to a significant decrease in precision. Furthermore, despite their consistency, robots can still be susceptible to wear and tear, which could impact their performance over time.

However, solutions to these challenges are continually being developed. With the advent of predictive maintenance, potential issues can be identified and fixed before they cause significant problems. By using machine learning algorithms, predictive maintenance tools can analyze data from the robot’s operations and predict when and where failures might occur.

As for calibration errors, the use of advanced sensor technology and machine vision systems can significantly improve the precision of robots. These technologies allow robots to precisely detect and measure their environment, leading to more accurate movement and task execution.

The need for advanced skills and knowledge to operate and maintain these sophisticated machines is another notable challenge. This has led to the rise of training programs and courses focused on robotics and automation, ensuring that the workforce is equipped with the necessary skills to keep up with the rapidly evolving technology.

The Conclusion: A Future Defined by Robotic Precision

Robots have firmly established their place in the manufacturing industry, and their influence will only continue to grow. Their ability to enhance precision, coupled with advancements in technology, promises a future where manufacturing processes are defined by an unprecedented level of accuracy and consistency.

However, like any technological innovation, robotics in manufacturing comes with its challenges. Yet, with the continuous development of solutions and the increasing capability of robots, these challenges are being systematically addressed.

The integration of AI and machine learning into robotics has set the stage for a new era of precision in manufacturing. These technologies not only enhance the precision of robots but also allow them to learn and adapt, resulting in improved performance over time.

In the quest for precision, robots have become more than just tools; they have become partners. Through collaborative efforts with human workers, robots can contribute to achieving a level of precision that was once thought impossible.

In conclusion, the future of manufacturing precision is looking more precise, consistent, and efficient, thanks to the remarkable capabilities of robots. As we continue to push the boundaries of technology, the role of robots in enhancing manufacturing precision will undoubtedly become even more prominent and indispensable. The era of robotic precision has only just begun, and we are excited to see where it will lead us.